Comment garantir à la fois un impact visuel fort et une utilisation efficace de l'espace pour un mur d'écrans LED suspendus ?

En pratique, les installations suspendues libèrent efficacement l'espace au sol et améliorent la flexibilité de l'agencement général. Elles offrent également au public une expérience visuelle plus immersive grâce à une meilleure hauteur et un angle de vision accru. De plus, sur les grandes scènes, les structures suspendues facilitent la coordination des systèmes d'éclairage, de sonorisation et de scénographie, pour un rendu scénique plus complet et harmonieux.

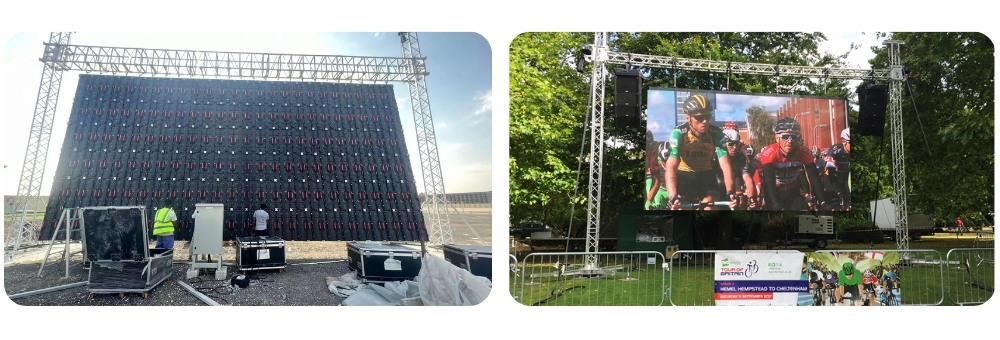

Pour ces raisons, les systèmes de structures en forme de poteaux de but sont largement utilisés dans diverses applications de suspension murale pour écrans LED. Ils répondent non seulement aux exigences d'installation d'écrans de tailles et de poids variés, mais peuvent également être ajustés avec précision en fonction des contraintes du site, ce qui en fait la solution privilégiée de nombreuses équipes professionnelles.

Défis liés aux murs LED suspendus

Bien que les murs d'écrans LED suspendus présentent des avantages, leur mise en œuvre concrète se heurte à de nombreux défis. Tout d'abord, le poids important des panneaux LED impose des exigences extrêmement élevées en matière de capacité portante de la structure supportée. Une conception structurelle inadéquate peut engendrer des vibrations, des déformations, voire des risques pour la sécurité, mettant ainsi en danger le personnel et les équipements sur site.

Les sites d'activités présentent souvent des contraintes d'espace, telles qu'une hauteur limitée, un terrain accidenté ou des allées complexes. Tout en garantissant la sécurité, il est également nécessaire de prendre en compte la visibilité du public et l'esthétique générale, ce qui impose des exigences plus élevées en matière d'aménagement.

De plus, la plupart des projets d'aménagement ont des cycles serrés et des délais d'installation et de démontage limités, ce qui rend l'efficacité de la construction primordiale. Si la conception structurelle est complexe et les étapes d'installation fastidieuses, cela augmentera non seulement les coûts de main-d'œuvre, mais impactera également l'avancement global du projet. Par ailleurs, une utilisation fréquente peut entraîner une fatigue de la structure.

Solution de système de treillis pour poteaux de but GF-Truss

Le système de structures à poteaux de but GF-Truss répond aux multiples exigences de stabilité, de sécurité et de flexibilité des applications pratiques des murs d'écrans LED suspendus. GF-Truss propose une vaste gamme de systèmes de structures à poteaux de but éprouvés et systématiques. Ces solutions utilisent toutes une structure en alliage d'aluminium haute résistance, combinée à divers composants standardisés tels que des sections supérieures, des manchons et des bases, pour former un système structurel stable, fiable et hautement modulable.

De par sa conception structurelle, GF-Truss prend pleinement en compte les différences de portée, de hauteur, de capacité portante et d'environnement d'installation propres à chaque projet. Grâce à une conception modulaire, le système offre une grande flexibilité. Qu'il s'agisse de petites scènes ou de grandes salles de spectacle, l'adéquation précise des dimensions structurelles et de la capacité portante est assurée par l'assemblage judicieux d'éléments de treillis aux spécifications variées. Cette conception améliore non seulement l'universalité de la structure, mais réduit également les coûts liés à la réutilisation du matériel pour différents projets.

Le système de structure en forme de poteau de but se combine facilement avec des poutres de suspension pour écrans LED, des palans et autres équipements, permettant ainsi une levée aisée de la paroi d'écran. Si vous devez fréquemment ajuster la hauteur ou la position de l'écran, ce système optimise considérablement l'efficacité opérationnelle et minimise les risques liés à la manutention manuelle. Il offre également une stabilité et une fiabilité exceptionnelles, que ce soit pour une installation permanente ou un événement temporaire.

GF-Truss prend pleinement en compte les différents scénarios d'utilisation, tels que les halls d'exposition intérieurs, les places publiques extérieures ou les sites au terrain complexe. Grâce à une configuration rationnelle des types de bases et des combinaisons structurelles, la structure en treillis assure un support stable quelles que soient les conditions du sol, offrant ainsi une fondation sûre et fiable pour le mur d'écrans LED.

Solutions variées de structures pour poteaux de but et possibilités de personnalisation

Forte d'une vaste expérience en matière de projets, GF-Truss propose à ses clients une gamme complète de solutions de portiques, couvrant différentes portées, hauteurs, capacités de charge et combinaisons structurelles afin de répondre à une grande variété de besoins. Que vous ayez besoin d'une configuration standard ou d'une solution sur mesure adaptée aux spécificités de votre chantier, GF-Truss vous accompagne tout au long du processus grâce à un support technique fiable et des conseils pratiques.

S'appuyant sur une équipe de conception expérimentée et de solides capacités de production, GF-Truss personnalise chaque structure en fonction de facteurs tels que l'agencement du site, la taille de l'écran et les exigences d'utilisation. Ceci garantit un équilibre optimal entre sécurité, stabilité et facilité d'utilisation. Grâce à des options de configuration flexibles, nos solutions répondent non seulement mieux aux besoins réels du projet, mais contribuent également à améliorer la rentabilité et l'efficacité de l'installation.

Conception structurelle et assurance de sécurité

Lors de la conception de chaque structure, une analyse systématique des forces sera effectuée afin de garantir une répartition optimale des forces entre les points d'application et d'éviter les risques structurels liés à la concentration des contraintes. Grâce à des calculs et des vérifications scientifiques, la structure globale atteint un équilibre optimal entre capacité portante et stabilité.

Pour les points de connexion critiques, nous utilisons des connecteurs haute résistance afin de garantir la stabilité du système sous charges dynamiques ou en cas d'utilisation prolongée. En particulier pour les applications d'affichage suspendu, la structure doit supporter le poids de l'équipement et les forces extérieures potentielles pendant de longues périodes, ce qui exige une rigidité et une durabilité accrues. L'optimisation des détails structurels améliore efficacement la résistance à la flexion, à la torsion et à la fatigue.

Concernant le choix des matériaux, GF-Truss utilise un alliage d'aluminium de haute qualité 6061-T6/6082-T6, alliant robustesse et légèreté. Ceci simplifie le transport et l'installation et réduit la charge structurelle totale au sol. De plus, toutes les conceptions structurelles sont conformes aux normes de sécurité en vigueur, garantissant une fiabilité durable pour les applications pratiques.

Efficacité d'installation et adaptabilité sur site

Lors de l'assemblage, l'efficacité de l'installation influe directement sur l'avancement global du chantier et les coûts d'exploitation. Afin de faciliter la construction sur site, tous les composants adoptent une structure standardisée et modulaire, permettant un assemblage rapide et une combinaison flexible de chaque pièce, ce qui simplifie considérablement l'installation. La construction peut ainsi être réalisée efficacement, même avec un personnel réduit ou des délais serrés. Ceci permet aux clients de raccourcir le cycle d'aménagement et d'améliorer l'efficacité de la construction.

Le système de structures en treillis pour buts de football offre une excellente adaptabilité sur site. Que ce soit dans des espaces intérieurs restreints ou en extérieur sur des terrains complexes, une construction stable est possible grâce à l'ajustement de la configuration structurelle et des méthodes d'installation. La flexibilité du système lui permet de gérer des hauteurs, des portées et des charges variables, garantissant ainsi une utilisation sûre dans des environnements divers. C'est pourquoi GF-Truss s'impose comme un partenaire structurel de confiance et durable pour de nombreuses équipes sur des projets à forte fréquence.

Laisser un message

Numériser vers WhatsApp :

Hi! Click one of our members below to chat on